Case History: Pumps as Turbines in the Water Industry

Allan R. Budris

Due to the heightened interest and feedback to the prior three columns on operating pumps as turbines (PaT) to recover energy, the writer approached several major pump manufacturers for actual field examples to share with the readers. Christoph Pauly of KSB was kind enough to provide the following Bryan Orchard editorial information about a very successful KSB PaT water application.

Pumps as Turbines

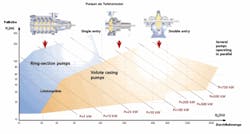

The behavior of a pump running as a turbine is very good, as the energy output can be higher than the energy input used to run it as a pump. Hydraulically, the pump in turbine mode can handle a higher volume of water than when in conventional pumping mode. There is a higher flow inside the pump and this means that the amount of energy that comes out is higher. An added bonus is that when it is in reverse operation and running as a turbine, the pump can run slightly more efficiently than in conventional mode. The operating range for ring section and volute casing pumps is illustrated in Figure 1. When the head is below 33 feet and flow rates are high, then axial flow pumps provide the most effective solution.

With the pump running in reverse (Fig. 2), the shaft torque can be utilized in a number of ways. When attached to a generator it is the power grid mains frequency that determines the speed. In such a scenario, to generate a frequency of 50Hz, the pump would have to turn at an exact speed of 1500 rpm. Incorporating frequency inverters and appropriate mains feed circuitry would create greater speed variation, without adding very much cost to the package. So it can be seen that this is a very cost-effective way of generating power, even when compared to the higher efficiencies of a conventional turbine.

This fact has not gone unnoticed by water utilities, operators of small hydropower plants, and pump manufacturers. Running pumps as turbines is an efficient method of generating energy, recovering energy and contributing to energy savings. In the current world economic climate, where reducing energy costs is becoming a high priority. It is not surprising that PaTs are starting to create significant interest.

Figure 1: The application range for ring section and volute casing pumps operating as turbines.

The Breech Plant

The significance of PaTs has not been lost on Zweckverband Landeswasserversorgung, one of Germany's largest drinking water suppliers. This regional water authority has harnessed the potential of eight KSB Etanorm 153-315, end suction pumps, to generate electricity for its own requirements and to feed the excess back into the national grid.

Through a mains network of over 480 miles across Baden-Württemberg and Bavaria, Zweckverband Landeswasserversorgung (LW) provides drinking water from three facilities in Langenau, Dischingen and Blaubeuren, to some 3.5 million customers. The amount supplied can reach 100 million gallons a day, a volume which requires a considerably large pumping infrastructure, along with the pipelines. The area is rich in water sources, and today approximately 50% of the water supplied to customers is drawn from the River Donar.

At 1480 feet, Breech is the highest underground reservoir in the supply system and it is from there that water is pumped down hill, some 30 miles to Stuttgart. The reservoir at Breech also houses a highly innovative and productive energy recovery system employing eight KSB Etanorm, horizontal, long-coupled, single stage, volute casing (back pull-out) pumps running as turbines, both to generate electricity and to control pipeline pressure. This facility augments other electricity recovery systems, to control pipeline pressure between the Osterbuch and Schönbhühl tanks.

"The objective of the Breech plant is to recover energy from the water entering the pumping station," reports Günther Störzer, of LW. However, it also has the pumping capability to return water to the incoming pipelines in an emergency situation. The plant has a reservoir capacity of 2.6 million gallons, and water enters the plant at approximately 72 psi through a pipeline into the reservoir. Normally, the water flows directly into the reservoir, but this would waste the potential energy of the water as it enters the reservoir. Rather than letting the energy go to waste, it is diverted through the PaTs at 4,600 gpm, and throttled down from 72 psi to atmospheric pressure before entering the reservoir.

The Breech experience

It was approximately 20 years ago that LW made the decision to replace the original pressure regulators with pumps as turbines, and in 1989 the first PaTs were installed, on very much of an experimental basis. After recognizing the benefits of this technology, a decision was made to install a permanent capability and KSB was awarded the contract to supply eight Etanorm end suction pumps for turbine duties. Constructed from cast iron, bronze and stainless steel, the internal surfaces are painted in order to provide additional resistance to any harmful effects of the water.

In order to optimize the flow and counter the possible effects of cavitation (resulting from the variations in both discharge and inlet pressure), the pumps have been installed at the lowest possible level. In addition, the maximum rotation speed of the pumps is kept as low as possible at 1750 rpm. A program has been installed to monitor and regulate the water flow and the speed of the turbines. This device regulates the turbine speed between 1499 rpm and 1504 rpm, and as soon as the speed reaches 1500 rpm, the generator is connected to the grid and the water flow regulated via a butterfly valve. This flow regulation is necessary to maintain the quality of the power being fed into the grid. The plant uses AC synchronous motors which are regulated by the grid itself, so the frequency comes from the grid. In addition, a special unit containing compensators, regulates the quality of the electricity between 0.9 and 1.0.

It should not be overlooked that the prime purpose of the Breech plant is to supply water to its customers. As a consequence, the water outflow will vary according to customer demand throughout the day. When demand is low, it is not possible to run all of the PaTs, but even with three units running, 170kW of electricity can be generated, while six turbines (PaT's) operating in parallel can generate 230kW.

Figure 2: KSB Etanorm pump in PaT operating mode.

The energy generated is used primarily for LW's own requirements, thereby reducing its demand on the national grid supply and lowering costs. The Breech plant is connected by cable to another pumping station, some 12.5 miles distant, in order to supply power for all of the pumps. The costs incurred have been recouped through the energy savings. For the whole of LWs operations, PaTs have been estimated to contribute to a saving of between 25% and 28% of the total energy costs.

An alternative approach for exploiting the energy of the incoming water to the Breech plant would have been to install a conventional turbine. However, the eight Etanorm pumps running in parallel represented a far lower cost option, and therefore a faster payback period. There is also an added advantage to using pumps rather than a conventional turbine, and that is that they give a greater range for regulating the flow of the water, plus they can be switched on and off according to the water flow.

When designing plants like the one at Breech, Günther Störzer says that it is important to take into consideration constant flow, as the pumps selected must be capable of running uninterrupted during the longest part of the day. It is far more cost-efficient to run the pumps for longer rather than short intervals (where it would become necessary to switch them on and off with changing flow demands).

"If you only have a certain amount of water available for a few hours a day, then optimized performance is achieved by using smaller units running for longer periods, rather than one large pump running for short periods," he said.

PaT/KSB Conclusions

Successful applications where KSB and other pump manufacturers already have pump units on PaT duties include: small hydropower systems (<10MW), major water transport systems, reverse osmosis and industrial systems, where the technology can be employed as an alternative to throttling devices.

In the low end market, power requirements are typically up to100kW, but the investment costs are relatively high for conventional hydropower units, which results in payback periods as high as 15 years. With the PaT solution, the payback period can be as short as 3 years, plus there is the added benefit that pumps are less complicated to operate than turbines.

An alternative application would be to connect a PaT directly to a driven machine, another pump being an example, which does not have either a motor or generator to fix the speed. This mechanical solution to providing energy has been successfully supplied by KSB to locations in many parts of the world, where a power supply is not available for operating water distribution/transfer pumps, but there is sufficient energy in head of water to drive a PaT.

The capability to operate multiple PaT modules in parallel is highly relevant for locations where the water supply can fluctuate. Unlike conventional turbines, PaTs do not have adjustable guide vanes for adapting to fluctuations in the water supply, and this is perceived as a drawback to their use. By employing a number of differently sized units to distribute the total volume of water available, this difficulty can be overcome. See November 2009 WaterWorld Pump Tips column which covers operating pumps as PATs in parallel operation. According to KSB, running several units in parallel requires only the minimum of control and, although this type of arrangement does diminish the cost advantage of the PaT over the use of a single turbine, it remains advantageous in terms of appropriate technology. Quite simply, pumps are easier to operate and maintain that conventional turbines.

WW

Contacts: Bryan Orchard, Orchard PR Limited, Email: [email protected]., Sander Klos, Senior Project Manager, Small Hydropower, KSB Aktiengessellschaft, Email: [email protected].

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles