Five ways water infrastructure can mitigate the effects of climate change

After decades of warning signs that climate change is happening, most people are now admitting that it is real — and it is not pretty.

Droughts are getting dryer, and floods are getting wetter and more frequent. Water resources organizations are struggling to manage ongoing crises and prepare for future events. While utilities cannot do much to significantly alter climate, they can help their cities to prepare to deal with the consequences and be more resilient.

Infrastructure remains one of the least technologically advanced sectors in the entire economy. A technological transformation of the industry has the potential to, among other things, help achieve sustainability and resilience goals against climate change, as well as improve the efficiency, safety, and quality of water infrastructure projects. Through new methods and new technologies, leading utilities are advancing the infrastructure on which society depends.

Here are five ways that digitalization and modeling can mitigate the consequences of climate change on a city’s water infrastructure:

1. Develop a contingency plan for droughts.

Seasonal droughts are worsening each year. Amid constant demand to optimize water resources, providers strive to maintain quality service and clean water supply to their communities.

It is important to have a digital representation that accurately reflects the physical network operation so that in times of trouble, teams can be prepared and in control. With advanced modeling and simulation, providers can essentially create the foundation for a true digital twin of the municipality’s macro water distribution and supply system.

An open modeling application provides a crucial feedback loop between the operations and engineering teams. The operations team brings field problems that engineering teams can dynamically assess through digital models. Both teams can collaborate and decide on optimal solutions, bringing a quick response with minimal impact to customers.

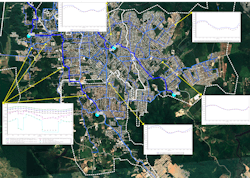

Joinville, Brazil is a city that experiences seasonal droughts, but in recent years it has been experiencing some of the worst droughts in 30 years. A hydraulic model and a digital twin helped Companhia Águas de Joinville to evaluate how well the system was working, as well as simulate what could be done within the system to figure out the optimal solution. BBC StoryWorks produced a mini documentary film about the Joinville experience.

2. Reduce nonrevenue water losses and waste

Water scarcity has the potential to affect more than half of the world’s population by 2025. A few simple steps can help bring better visibility of water distribution network assets, reduce waste in processes, and save millions of gallons of water annually.

First, optimize operational activities to prevent pipe bursts. Monitoring operations of the water supply system can find and fix leaks faster and extend the operating life of infrastructure. This process saves resources required to keep the assets running safely and reliably. In addition, remote monitoring capabilities could mean fewer site visits and reduced fuel and labor costs.

While hydraulic models in the past were mainly used by the engineering department, they can now be used easily for daily operations and maintenance. The advantage here is that with a cloud-based digital twin, real-time simulations of network events, such as pipe breaks, pump shutdowns, valves operations, water flows, and fires, can help to better understand and anticipate the impacts on service levels.

Water digital twins bring together SCADA, GIS, hydraulic modeling, and customer information into a connected data environment to deliver cost-effective operations and maintenance strategies in real time. With real-time hydraulic analysis of the network on-hand, operators can fill in the gaps between sensor data.

With visibility to the system’s sensor data, boundary conditions, billing, and hydraulic modeling information in real-time, this digital twin continuously monitors all infrastructure assets, including tanks, pumps, pipes, and valves. It provides at-a-glance visibility to key data points, including valve operational status, tank level, and input flow for each district metered area.

The digital twin provides visibility into non-performing assets and anomalous network conditions. In addition, utilities gain visibility into present, historic, and forecasted analysis of the performance of assets to uncover leaks in the network before they turn into a problem, and to proactively identify areas of improvement.

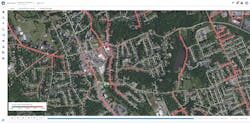

In Manaus, Brazil, AEGEA integrated key data that was previously stored across different siloed systems into a single platform to improve leak detection, asset management decisions, and operational processes.

3. Conduct flood risk assessments

When flooding poses risks to residents, damages property and infrastructure, and disrupts urban services, hydraulic simulations can help engineers and operators to predict and better understand problems and create efficient solutions that increase the resilience of urban drainage systems.

Powerful tools for flood modeling and hydraulic analysis of overflowing stormwater systems are important to prepare for new challenges in water retention for both urban and city environments. With comprehensive visualizations, both engineers and non-engineers can make more informed decisions aimed at assuring service levels and improving stormwater collection network and asset performance.

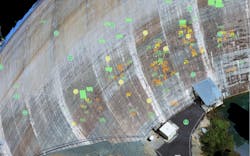

Wastewater and stormwater condition assessment is a costly and constant activity for city workers. Intelligent and automated rapid condition assessments use machine learning to improve defect detection and labeling, improve data quality, accelerate inspection work, and reduce costs.

Integration with the digital twin makes this data part of a systematic process that water and wastewater professionals use every day. It puts valuable analytics and timely decision support at the fingertips of operations and maintenance to help them understand and proactively mitigate the impact on flows based on forecasted weather patterns, especially crucial during extreme weather events.

Urban drainage networks are intended to safely collect and convey sewage and stormwater, but the reality is that many existing systems have problem areas where the flow is not effectively contained. Digital tools help engineers to determine the extent to which undesirable overflows will spill, and to understand the root causes of a problem.

In 2020, significant flooding along the Yangtze River killed 141 people and displaced 38 million more. For the city of Jiujiang, the disaster was the latest in a string of overflow and waterlogging incidents caused by accelerated urbanization, and officials initially could not determine how to prevent them.

To better prepare for future flooding events and minimize disruption to city life, China Three Gorges Corporation directed Shanghai Investigation, Design & Research Institute (SIDRI) to create a hydraulic analysis system that can simulate a variety of water conditions in the city.

To provide the information, the hydraulic analysis system would need to clearly display detailed data, plan flood control tasks, and pinpoint emergency events. Frequently updated hydraulic data needed to be easily accessible to shorten the time to dispatch emergency services.

With the ability to predict potential waterlogging, officials can now identify and address critical drainage problems in advance. Real-time data overlaid onto the reality model allows the city to make emergency responses to flooding in a timely manner.

4. Prepare for rapid response with dam safety monitoring.

Dam failures can be catastrophic, so it is essential for dam owners and inspectors to implement tools that effectively and proactively reduce these risks to people and the environment. A self-sustaining dam safety monitoring system uses a network of sensors to monitor conditions including rainfall, pore pressure, deformation, reservoir lake level, and other metrics to provide automated site-specific insight into the performance of the dam and the water distribution system.

In the case of Hurricane Ida, such data was used to establish alerts that, when thresholds or predefined warning limits were exceeded, triggered notifications autonomously sent to key engineers and authorities. A dam safety engineer on duty at the time was able to alert affected counties to conduct evacuations in a timely matter when multiple dam sites lost power. Through the use of real-time automated monitoring, the dam safety officer was able to react to rapidly deteriorating conditions that nearly reached overtopping conditions and maintain an enhanced safety response for the surrounding areas.

5. Reduce carbon footprint and aim for net zero.

One way to become carbon neutral by 2030 is to reduce energy consumption and carbon emissions. Water utilities are some of the largest users of electricity, and so energy potentially represents the largest controllable operational expenditure in a utility, making it a perfect target to help minimize environmental impact.

Digitizing the water supply network and implementing smart, energy-efficient pumping operations helps to achieve sustainability and eco-friendly goals without impacting service quality, such as water pressure or water quality, for their customers. Hydraulic models can be used to instantiate energy savings by reducing energy waste and promoting better efficiencies in operating a pumping system.

Optimizing pumping station operations can lower fuel needs and reduce electricity usage. The best way to automate the on/off pump switches is through a digital model, calibrated and simulated to accurately represent water supply operations in real time.

Evides supplies the Netherlands’ city of Rotterdam with clean and safe drinking water. They coupled the hydraulic model with an optimization algorithm using dynamic control scripting. They used the model to test, evaluate energy cost calculation, and automate the on/off switch points to optimize usage of the pumping stations for 110 million cubic meters of pumped water. Evides was able to save 33 percent in energy costs and reduce their carbon dioxide footprint by 942 tons. Energy costs savings of EUR 300,000 annually was achieved, reducing the carbon footprint and contributing toward sustainability company goals.

Advancing Utilities – It’s About Time

Leading utilities are advancing their digitization to help achieve sustainability and resilience goals against climate change, as well as to improve the efficiency, safety, and quality of water. Through new methods and new technologies, utilities can mitigate the consequences of climate change on their cities’ water infrastructure.

About the Author: Sandra DiMatteo is the industry marketing director for water infrastructure at Bentley Systems. She can be reached at [email protected].

About the Author

Sandra DiMatteo

Sandra DiMatteo is the industry marketing director for water infrastructure at Bentley Systems. She has more than 25 years of experience in reliability and asset performance management software and asset lifecycle information management.