Comprehensive workflows to catch PFAS contaminants

Per- and polyfluoroalkyl substances (PFAS) are emerging as a primary environmental contaminant. These compounds have been used in a variety of products since the 1940s, from food containers and non-stick cookware to cleaning products, textiles, packaging materials and aqueous firefighting foams. While useful for manufacturing, PFAS contamination has become prevalent in everything from water sources to the food chain. Moreover, studies show that over 97 percent of Americans have bioaccumulation of PFAS compounds in their bloodstream, with evidence of adverse impacts on health1.

While there are many efforts to reduce PFAS in commercial products and manufacturing processes, these chemicals are still in use today. Also, numerous products which were produced in the 20th century can still be found in older homes, vehicles, and other products. These can be sources of PFAS contamination when thrown away. Moreover, the number of new PFAS compound types are growing as industry sectors invent new forms of these substances for different products.

Because of the health and environmental concerns surrounding PFAS, it is critically important to monitor the presence of these compounds to identify risks to public health. This is especially true for the water supply and soil, as they present chances for PFAS to bioaccumulate. Here, we discuss how new technologies enable testing laboratories to gain the upper hand in identifying PFAS contamination of water samples in efficient timescales.

The Challenges of PFAS Analysis

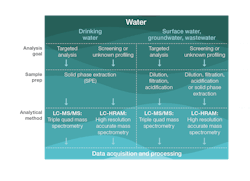

Several national and international regulatory bodies have developed methods specifically for the determination of PFAS of specific concern in different sample types2. These workflows use different sample preparation methods, followed by liquid chromatography-tandem mass spectrometry (LC-MS/MS) technologies to detect low concentrations of PFAS compounds in the low ng/L range. However, laboratories performing any type of PFAS detection are often faced with a series of challenges to obtain reliable and comprehensive results.

One of the challenges of PFAS sampling and analysis begins with a simple problem. A representative sample must be obtained without introducing any background contaminates; no mean feat when PFAS compounds can be found in many sources when sampling and in the laboratory, like flasks and tubes. As such, sampling must be performed with specialized polypropylene products free from PFAS compounds, and by avoiding contamination from other common PFAS sources. It is also important to use instruments with minimal fluoropolymers.

At the analysis stage, many laboratories often see challenges in monitoring the wide range of potential PFAS variants in samples. The list of unknown variants to analyze is growing, and many PFAS and their precursors are not accounted for by existing analytical methods. Current regulations define a set list of contaminates to detect, which can be performed with targeted analysis in LC-MS/MS systems. However, this method can miss emerging contaminates. As a result, there is a growing need for efficient analytical workflows that have the flexibility to measure known PFAS contents with high accuracy or identify possible unknown PFAS contaminants in water samples.

Recent advances in mass spectrometry and sample preparation methodologies, however, are enabling laboratories to perform targeted analysis of known PFAS in water samples, while others detect often-elusive PFAS compounds more effectively than ever. These workflows utilize new automated technologies to streamline sample preparation, and increase the efficiency of MS.

Sample Preparation

Drinking water samples are typically prepared using a solid-phase extraction (SPE) workflow followed by analysis using LC-MS/MS. However, these methods can be time-consuming and complex. Traditional SPE methods are performed with a vacuum manifold, which is a fully manual process that requires the addition of multiple solutions and rinses over time. The number of phases can lead to human-errors, increasing the risk of background contamination.

However, new, automated SPE technologies now exist, which provide reliable determination of PFAS in large-volume samples with minimal user interaction. As well as improving workflow efficiency, automation of sample preparation workflows helps to reduces background noise in a sample.

For surface water, groundwater and wastewater samples, direct injection methods are often preferred, as these typically “dirtier” samples run the risk of particulates blocking filters. These methods are based on sample dilution, filtration and acidification. Current sample preparation and analysis workflows use specialized instruments designed to ensure inertness and reduce the risk of background PFAS contamination.

Targeted Analysis Workflows

Following sample preparation, targeted screening is usually performed with an LC-MS/MS system that enables highly accurate results for targeted readout of a known list of PFAS compounds to fulfill United States Environmental Protection Agency (EPA) method requirements.

While SPE and LC-MS/MS-based methods are typically used for quantifying the amount of known PFAS analytes in a water sample, they are not designed to determine the presence of other, unknown PFAS compounds that are not expected to be present. For unknown compounds, another complementary screening method is required.

One such method is combustion ion chromatography (CIC), which analyzes the content of adsorbable organically bound fluorine (AOF) in a sample to determine if the total amount of fluorine is higher than the amount of PFAS content confirmed in earlier LC-MS/MS measurements. If fluorine content is higher than expected, this indicates the possible presence of unknown PFAS compounds that are not readily determined by targeted LC-MS/MS.

While ion chromatography cannot be used to directly analyze PFAS, adding the combustion unit can be used to determine levels of adsorbable organic halides, which includes fluorine (AOF). CIC provides a fast, precise and reproducible way to measure general PFAS content in water samples. This can be performed on surface water, groundwater, and wastewater samples alike.

However, there are other organic molecules which have organically bound fluorine, such as pesticides and pharmaceuticals. Therefore, non-targeted screening of the sample should first be performed with high-resolution mass spectrometry (HRMS) to discover the identity of these other compounds. Significant advances in HRMS technologies in recent years also mean this method can detect a vast range of potential contaminants in complex samples with high accuracy.

A Dual Workflow Approach to Rooting out PFAS Contaminants

PFAS compounds are emerging as one of the primary contaminants of the environment, and their propensity for bioaccumulation in the human body poses concerns for long-term health. PFAS samples can leach into water sources from manufacturing processes and poorly disposed PFAS-containing plastic products, and do not readily break down.

Recent advances in mass spectrometry workflows have made monitoring PFAS contamination simpler and more cost-effective for water testing laboratories. SPE methodologies combined with targeted analysis using LC-MS/MS allow highly accurate results of known PFAS compounds in a sample. SPE-based methods can also be combined with known screening methods using HRMS to measure the presence of unknown PFAS compounds in water samples. With this dual approach, laboratories can increase the range of potential targets monitored and confidence in assignments by reducing false positives. It also provides a powerful way to screen suspicious samples rapidly and effectively.

References

1 Lewis RC, Johns LE, Meeker JD. 2015. Serum Biomarkers of Exposure to Perfluoroalkyl Substances in Relation to Serum Testosterone and Measures of Thyroid Function among Adults and Adolescents from NHANES 2011–2012. Int J Environ Res Public Health. 12(6): 6098–6114

2 U.S Environmental Protection Agency (EPA). Method 537_FINAL_rev1.1 Determination of Selected Perfluorinated Alkyl Acids in Drinking Water by Solid Phase Extraction and Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/MS) (Sept,2009), 2009. https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=P100EQ6W.txt

About the Author: Chris Shevlin is the scientific and educational affairs manager with the Ion Chromatography and Sample Preparation group at Thermo Fisher Scientific. In 2015, he joined Thermo Fisher Scientific, first selling IC, GC and LC systems before moving into a marketing role for ion chromatography and automated sample prep instruments. In 2021, Chris took on the new role as scientific and educational affairs manager.