By Fred Wiesler

Proper treatment of boiler feed water is an important part of operating and maintaining a boiler system. As steam is produced, dissolved solids become concentrated and form deposits inside the boiler, leading to poor heat transfer and reduces boiler efficiency. Dissolved gasses, such as oxygen and carbon dioxide, react with metals in the boiler system, resulting in boiler corrosion. These gasses should be controlled or removed to protect the boiler.

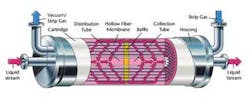

Schematic of the Liqui-Cel Membrane Contactor. Provided by Membrana

Several different technologies are widely used in the industry to remove these contaminants. Reverse osmosis membrane and ion exchange systems can remove dissolved solids. Forced draft degasifiers, chemical agents and steam de-aerators have historically been used to remove dissolved gasses.

Membrane contactors are increasingly being used to remove dissolved gasses in boiler feed water. Widely used in the semiconductor, power, pharmaceutical and other industries to control dissolved gasses in water systems, their use in boiler feed water degasification systems has grown steadily since the development of new industrial grade devices.

Membrane contactors contain microporous hydrophobic membranes, which are used to bring gas and liquids in direct contact without mixing. Contactors operate by lowering the pressure of gas in contact with the liquid to create a driving force to remove the dissolved gasses from the water. They are highly efficient and compact, and can be used inline under pressure.

Chemical treatment

Chemical treatment is widely used to control dissolved oxygen in a boiler. The cost of operating a chemical treatment program consists of chemical costs and blow down costs. As the water is converted to steam, non-volatile compounds in the boiler feed water are concentrated inside the boiler. Periodically the water in the boiler must be flushed out to remove these compounds by a process called blow down. Any chemical that is added to the water can increase the frequency of blow down, which affects operating costs of the boiler.

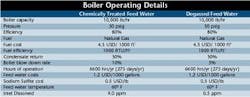

Table 1

The cost of blow down can be broken down into two costs – water and heat/energy. First, water and steam that is purged from the boiler during blow down is drained, so this water must be replenished by fresh makeup water. Second, the water blow down from the boiler is hot and is replaced with cold water that must be reheated to produce steam. Energy costs can be calculated by looking at the energy needed to heat the water back to the temperature of the steam produced by the boiler.

In smaller low-pressure boilers (<10,000 lbs/hr and < 50 psig), chemical treatment alone may be used; a combination of steam deareation and chemicals is most often used for larger high-pressure boilers. For ease of calculation, a small low-pressure boiler using a chemical program only will be evaluated in this paper. These same calculations can be used to evaluate boilers that use steam deareation. When evaluating a deareator, the cost of operation should also be included. The operating cost of the steam deareator can be estimated by calculating the extra feed water required to operate the deareator and the energy loss associated with venting the steam deareator.

In practice, 10 ppm of pure sodium sulfite is needed to remove one ppm of oxygen from water. One ppm of sodium sulfite equates to 8.3 lbs per million gallons of water. The amount of dissolved oxygen in the water varies with the water temperature. If 10 ppm of oxygen is dissolved in the water, 83.0 lbs of sodium sulfite will be required per million gallons of water.

Table 2

The price of sodium sulfite per pound can be multiplied by the above relationship in order to calculate the chemical costs per gallon of water treated.. The feed water flow rate is the amount of water that is added to the boiler. The feed water rate is equal to the boiler capacity + water loss in blow down – condensate return.

Chemical costs are directly associated to the gallons of water treated and the inlet dissolved oxygen level in the feed water.

The cost of water lost during blowdown can be calculated by multiplying the amount of water lost during blow down by the water costs. The energy costs associated with heating the water can be estimated by calculating the extra energy needed to heat the feed water. Since the feed water is at ambient temperature and must be heated in the boiler, heat must be added to the water. The difference in enthalpy of the steam and the feed water is essentially the difference in the heat content of the feed water and steam in the boiler.

Energy costs can be calculated with the fuel cost, energy content of the fuel and the change in the enthalpy of the water. The enthalpy of water at 60ºF is 28 BTU/lb. The enthalpy of steam at 50 psig is 297 BTU/lb.

By removing dissolved oxygen from water, membrane contactors reduce the volume of chemicals added to the boiler and potentially reduce the frequency of blow down. The example below compares operating costs of two systems. One system is a chemical-only treatment system with a blow down rate of 10%. The other system assumes that the oxygen content of the feed water is reduced to 0.5 ppm and that the blow down rate can be reduced to 5% due to the reduction of chemicals in the boiler.

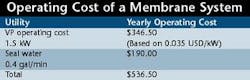

Table 3

The boiler specifications used in this example are for reference only and used so actual calculations can be shown in Table 1. These calculations can be modified in order to apply them to boilers with different operating conditions.

Membrane system operating costs

A membrane system can be used to produce feed water with low levels of dissolved oxygen. The running cost of a membrane system includes electricity and seal water for a vacuum pump. The costs for a system designed to operate at the conditions above is outlined in Table 3.

The operating cost of the membrane system is less than US$ 550 dollars per year, which saves US$ 1,600 per year compared to the chemical costs in a boiler that only uses chemicals to treat dissolved oxygen. Operating cost savings jump to more than US$ 8,000 per year when including blowdown costs. A typical membrane system designed to degas the water outlined in this example can reach payback in less than two years.

Many boilers use a steam deareator to degasify boiler feed water. These devices use steam that is produced by the boiler to remove dissolved oxygen. The steam preheats the feed water and strips out the dissolved gas. Some portion of this steam must be vented off to remove the gasses from the system.

This venting is essentially a loss of energy and can be calculated in the same manner that the energy loss associated with blowdown was calculated. Steam deareators typically need to vent approximately 10% of the feed to the deareator to purge the dissolved gasses from the water. They also need to operate at 2 to 4 psig. During peak operating times the pressure may be difficult to maintain so additional boiler capacity may be required. These added boiler loads should be included in an operating cost analysis.

Shen Lan Environment Inc., located in Shanghai, China, uses Liqui-Cel® Membrane Contactors in their boiler feed water treatment systems. These systems reduce operating costs and the volume of chemicals added to the boiler feed water.

Summary

Dissolved oxygen control in boiler feed water protects the boiler from corrosion. Liqui-Cel Membrane Contactors can be used to replace or supplement the chemical treatment program, which is often used to control dissolved oxygen. The contactors can minimise the volume of chemicals added to the feed water and offer savings to the end user by reducing chemical and energy costs.

Author's NoteFred Wiesler is a technical sales manager in the Industrial Separations Group of Membrana, located in Charlotte, North Carolina, USA, who is currently responsible for sales and service of Membrana's Membrane Contactor product line for Asia. Mr. Wiesler has more than fifteen years experience in the field of membrane separations and holds patents on membrane contactor designs.