Continuous Backwash Filter

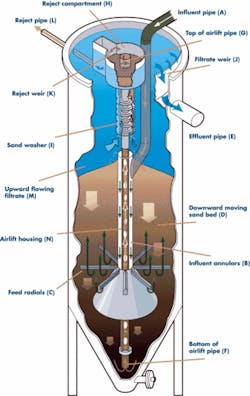

Click here to enlarge imageIn the following paragraph, we will describe how the continuous backwash filtration system works, as illustrated in the figure on the previous page. Influent is introduced into the filter through the feed inlet pipe (A) and flows down through the feed assembly pipe (B). Then, the flow enters into horizontal distributors, also called radial arms (C), which protrude into the filter. These distributors allow even distribution of the influent into the sand bed. The influent is then filtered upward through the sand. During this upward filtration, the sand bed (D) constantly moves downward and clean filtrate exits from the sand bed through an effluent pipe (E).

An internal airlift (F) transports a portion of the contaminated sand media and discharges to a reject bowl/chamber (H) at the top of the filter unit. The agitation and turbulence within the airlift clean the sand of the filtered solids. Due to gravity the sand, which is heavier than the organic solids, captured in the bed falls down through sand washer (I).

The washer/central compartment section is isolated from the filtrate, except where the sand exits at the bottom of the washer. Treated effluent flows over the effluent weir (J) and the reject flow over a reject weir (K), leaving the system through a reject pipe (L).

During sand storms, especially arid environments such as in the Middle East, self-cleaning deep bed filter becomes necessary to maintain the desired suspended solids in the cooling tower water loop.

Comparing with other available technologies, sand filtration with continuous backwash seems to be the right technology for side stream filtration.

WWi

Author’s Note:

Mohamed Ahmed Salah, P.Eng., is a regional manager with the Parkson Corp. A subsidiary of Axel Johnson Inc., Parkson is a supplier of solutions for potable water, process water, and industrial and municipal wastewater treatment. With multiple offices the USA, Canada, Brazil and the United Arab Emirates, it’s based in Fort Lauderdale, Florida, USA. Salah operates from Florida and Dubai. Contact: [email protected] or www.parkson.com