A typical DynaOxy installation for ammonia nitrification

Click here to enlarge imageIn the UK, the Environment Agency and the Department for Environment, Food and Rural Affairs (DEFRA) support a focus on “Joined up Government” as the way forward - an approach that integrates the activities of wastewater treatment with other contributory factors and considerations, particularly agriculture, land use planning, biodiversity, tourism, leisure and recreation, flooding and health. Ammonia pollution is a key consideration in all of these. First, it is a cause, such as through agricultural practices. Second, it is a disseminator; storm water flooding and run off can instigate pollution incidents. Finally, the pollution may affect biodiversity, river and coastal tourism and leisure.

Joining up the reduction of agricultural ammonia generation and diffusion problems with land use planning is a major start. More than 80 percent of the ammonia produced in the UK is agriculturally derived. Co-ordination of planning licenses for new pig or poultry units with the strategy for sensitive habitats downstream in the river basin is essential to ensure that the effects of eutrophication and excess nitrification are minimized.

Role of wastewater ammonia treatment

To supplement the agricultural initiative, the agencies are also concerned with discharges from sewage wastewater treatment plants. Although treated effluent contributes a much smaller source of ammonia, reducing the quantity of wastewater treatment discharge can help significantly reduce the total ammonia and nitrogen amounts below critical load thresholds.

Nitrogen reduction in discharge waters from wastewater treatment plants is based on the production of relatively inert, dissolved gaseous nitrogen by harnessing the bacteria in urea and providing the right conditions for the right species of bacteria to flourish.

Conventionally, this process takes place in basins that require significant tank volumes. Many treatment plants are too small to accommodate the volume required, and attempts to achieve this through increasing sludge concentrations and sludge residence can lead to other problems. In addition, settling tanks for removing the bacteria may be required.

Some older treatment plants have horizontal sand bed filters, which allow the bacteria to settle on the solid surfaces of the sand, achieving much higher concentrations than in open tanks and thus provide a large surface area for action. However, these plants occupy much space and need equipment for dispersing raw fluids that require maintenance. Additionally, these have a fixed useful life and possible major costs, as the filter beds get clogged and must be dug out and disposed or even abandoned.

Saving space and operational costs

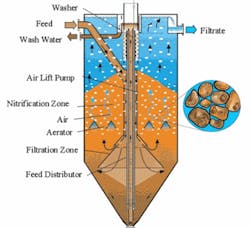

An alternative solution is to install upflow vertical tank biological sand filters, which require typically one-tenth of the space required by the conventional basin alternative. By continuously cleaning the sand, the effectiveness of the filter system is maintained and sediments can be washed out for disposal. Continuous sand cleaning also maintains the health of the bacterial population. Bacteria remain in the sand as the water flows up through the sand and through an undisturbed upper volume in water to cascade over a weir. This feature eliminates the need for additional settling tanks to remove bacteria from the water.

Long-term filtration and nitrification

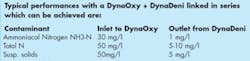

The DynaSand filter uses the upflow principle and contaminated sand is also circulated constantly via an airlift pump. Thus, for a small power input, cleaning of both the water and the sand is continuous and the filter need never be shut down. The diagram shows the operating principle that has been used for tertiary filtration after post-sedimentation to separate particles and lower the phosphorous content of the water.

This process has now been further developed to provide highly effective treatment for the removal of ammonia from the water by creating favorable conditions for treatment bacteria to flourish within the sand filter. As the biomass and sand are continuously moved through the filter and the most favorable conditions for growth, the filters are also very tolerant of ammonia surges.

Aeration hoods fed by process air are sited within the upper layer of sand to ensure that the autotrophic nitrifying bacteria - Nitrosamonas and Nitrobacter spp. - have sufficient oxygen and CO2 to convert ammonia to nitrates. This mixing action provides sufficient aeration and the resultant nitrates are dissolved in the water. This version is termed the DynaOxy.

The DynaDeni filter can provide denitrification as part of the treatment package by being configured without the aeration hoods and a deeper filter bed. This enables more anoxic conditions to be created allowing the denitrification bacteria to flourish using a controlled dose of methanol as a carbon source, and allowing the nitrogen to be released as gaseous nitrogen to the atmosphere.