Are you in the market for a new sludge pump because your current positive displacement pump has leaky seals, runs dry then breaks down, clogs often, needs frequent maintenance or is too complicated to repair? If so, then it is time to consider an alternative positive displacement pump design.

Positive Displacement Pump Technologies with Negative Consequences

Progressive cavity and rotary lobe pump technologies are found in municipal, industrial, chemical and food processing industries. These pumps are based on a close tolerance design within the pumping chamber and use a rubbing action to generate flow. Because of these close tolerances, pumps begin to wear the minute they are turned on. This wear pattern causes the pumps to lose efficiency over time and require the operating speed to be increased to maintain the design flow rate. By increasing the speed, the wear rate is increased exponentially. This pattern continues until the flow rates drop to a point where the pump needs to be rebuilt.

Due to the close tolerances of these styles of pumps, any grit or abrasive material wears them out at an even faster rate. These pumps are also unable to pass large solids and rags through their system, so a grinder must be used on the suction side to protect the pump from clogging and damage.

The replacement parts for rotary style pumps are extremely costly and the replacement process can be very complicated. They typically use expensive mechanical seals or a stuffing box with a packing gland that will leak. Because of this, these pumps are often sent out for rebuild due to the size or complexity of the problems they experience. This can result in facility downtime when the pump is out of operation, creating further issues for the user like drops in production efficiency and increases in costs.

Solving the Problem for Good

In an effort to keep applications like municipal wastewater sludge; scum and slurry pumping; dewatering feed; lime sludge and slurry pumping; fats, oils, grease and food waste pumping; as well as chicken and beef waste processing and rendering plant waste pumping; and industrial wastewater sludge handling running smoothly, a pumping system that does not rely on close tolerances to generate flow is key.

A Double Disc Pump is designed to do just that. It does not rely on close tolerances to generate flow. Its reciprocating valving action produces a light, low friction touching action of the discs on the seat which correlates to a very low wear rate. Unlike other pump technologies, the non-close tolerance design of the Double Disc Pump can handle applications with entrained grit and abrasives. There is less wear in the pump operation itself, so handling grit and abrasives does not drastically increase wear rate.

Double Disc Pump Technology

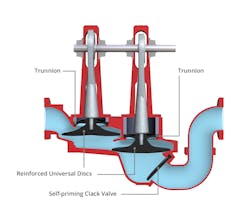

The Double Disc Pump is a reciprocating positive displacement pump based on the induced flow principle. Induced flow happens when a vacuum is created due to the reciprocating nature of the pump and the fluid fills the vacuum void.

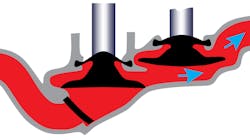

Through a drive shaft, connecting rod and cam arrangement, the discs are rotated 180˚ out of phase, performing the duties of pumping and valving during operation. During the suction cycle, the suction disc lifts off its seat, creating a vacuum while the discharge disc is seated filling the cavity within the pump. The discharge cycle creates pressure above the suction disc causing this disc to seat and forces flow out through the discharge.

Since the discs are mechanically placed on the seating surface, they positively valve on every revolution reducing the potential for loss of flow on debris-laden and stringy material. This is vastly and uniquely different than a mechanical diaphragm pump or plunger pump that uses an internal flapper or ball check valve that relies on gravity seating to positively seal. When debris is trapped under a flapper or ball check valve, the pump stops pumping and requires cleaning of the valve for proper operation to continue.

The flexible elastomeric discs in a Double Disc Pump are not captive in the pump housing. This eliminates the flex fatigue failures experienced with captive mechanical diaphragm pumps. This also enables a virtually clog-free and failure-free pump system. If debris under 2 inches in diameter is caught under a disc, it is flexible enough to still seal around it. When the disc moves again during the next cycle, the reciprocating action of the fluid flow through the pump moves the material out of the pump. Since the Double Disc Pumps does not rely on internal flapper or ball check valves for valving, the pump is able to pass material that causes other pumps to clog and stop pumping.

The Double Disc Pump is unique because there are two, non-captive discs working simultaneously to generate flow. The pump has a very short stroke length and provides a small displacement per stroke, allowing it to operate at higher speeds. The small displacement per revolution provides for a relatively smooth flow compared to traditional reciprocating pumps. The use of pulsation dampeners helps to reduce the small pulse in flow, allowing the pump to be used for pulse sensitive dewatering operations that cannot be handled by typical reciprocating pumps.