Taking the Rains: Examining Stormwater Collection and Treatment Methods for Reuse

By Lori McPherson

Water is emerging as a significant environmental concern around the globe. Worldwide water consumption is rising at double the rate of population growth, and in less than 20 years, 1.8 billion people will be living in areas with water scarcity. Within the next five years, areas in at least 36 states across the U.S. are expected to have water shortages because of a combination of rising temperatures, drought, population growth, urban sprawl, waste and excess. As such, both the scarcity of freshwater resources and the costs of capturing, treating, storing, transporting, and distributing water make effective stormwater reuse a priority.

The collection and treatment of stormwater for reuse is a growing market that enables this water to be used for a variety of applications including irrigation, non-potable applications (toilet flush water), process water or cooling tower feedwater (industrial), and occasionally even for potable (drinking) water. Turnkey systems are available that capture, measure, control, and deliver harvested rainwater treated as necessary for the intended use. Likewise, automated controllers enable complete system control from simple to more sophisticated systems, including the ability to datalog system parameters and the amount of water processed so that return-on-investment (ROI) savings can be calculated.

Stormwater reuse can also reduce the load on wastewater treatment plants. The installation of a stormwater harvesting system makes good economic and environmental sense and will often pay for itself in less than two years. In recent years, there has been much interest in green building, and water efficiency has become an important aspect of the program. The U.S. Green Building Council's LEED green building certification program now requires a 20-percent reduction in water use as a prerequisite for project certification.

Uses

The most popular use for harvested stormwater is for irrigation, which accounts for approximately 34 percent of all water use in the United States. Replacing just a small portion of this with harvested stormwater can result in a significant reduction in water costs. Further, the treatment required to reuse stormwater for irrigation is minimal, enabling the systems to be very affordable and simple in operation. Many homeowners have installed very simple barrel systems that collect rainwater from existing gutter plumbing that is used for irrigation.

Another common application for harvested stormwater is for toilet flush water. This application is commonly used in schools and other small institutional facilities. A dye will normally be injected into the water collected to differentiate it from potable water. These systems can be more complex if there is a connection with city water systems, but there are many manufacturers who specialize in these systems and have made some standard designs very affordable.

In the industrial environment, irrigation costs are generally insignificant compared to the costs for water used for cooling and process water. These applications often account for 80 to 90 percent of industrial water use and are generally the most complex, with enhanced filtration, disinfection, recirculation, and water quality monitoring. However, there are many companies that specialize in providing complete turnkey systems.

Treatment

Effective stormwater management practices include the installation of reliable storage, treatment, measurements, and procedures to protect and improve water quality. There are many options available for treatment systems depending on the intended use of the stormwater collected.

Obviously, water used for irrigation or non-potable uses (flushing toilets) requires significantly less treatment than water used for potable or other industrial uses. A user would also want to consider whether to use an in-ground or aboveground storage tank. The size of the tank being utilized can be calculated based on the size of the collection area (generally a roof top) and the average rainfall amount. It is also feasible to have a primary collection (dirty) tank with an additional storage (clean) tank. A system recirculating water from the clean tank and back through treatment is also commonly installed.

The initial collection of stormwater can pick up debris, chemicals, dirt, and other pollutants. Most systems utilize controls that enable the first inflow of water to be diverted to waste as a means to carry a majority of the debris and pollutants away. A method of course filtration is then used on the remaining water to remove particulate matter and oils. Once the rainwater has been filtered and collected into a large storage tank, a pump is required to transfer the water through the subsequent treatment steps and into the clean storage tank or directly into the system or where it will be used. Underground collection tanks generally use a submersible pump inside the tank, whereas aboveground tanks (collection and/or storage) generally utilize a standard centrifugal pump. Low-level cut-off switches in the collection/storage tank are essential to protect the pumps from running dry. Further, a floating draw-off enables the pump to pull from the cleanest (top) part of the tank and allow any residual debris to remain on the bottom.

If the system is to provide potable or clean process water, additional treatment would likely include standard flocculation and precipitation, followed by fine filtration to remove the impurities in the water. A method of disinfection, either chemical (bleach) or UV treatment, may be utilized to prevent microbial organisms and biofilm from forming in the piping systems. If the system has a connection to a domestic supply (for when rainwater is not available), pressure regulators, check valves and backflow prevention devices would be required. Additional rainwater system options can include a cistern, booster pump and/or hydropneumatic tank. The hydropneumatic tank (pressured with air) can provide a consistent pressure in the system and prevent water hammer. For more sophisticated systems, a manufacturer or environmental expert should be brought in to assist with the project.

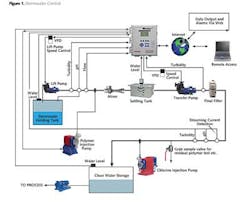

Control

Control for a stormwater harvesting system may include data collected from flow meters, level sensors and water quality measurements, which may include pH, conductivity, temperature, streaming current, oxidizing reduction potential (ORP), and/or turbidity. The planned use for the collected, treated water and the treatment process will dictate which measurements are important. Ideally, the controller would have the ability to datalog all parameters and communicate when there is an abnormal situation so that corrective action can be taken immediately.

The controller should have the capability to interface with the analytical sensors so that calibration and other diagnostic information can be evaluated. The analytical measurements can provide important data such as: pH to ensure the water will not cause corrosion or scaling in the piping systems; conductivity to monitor the total dissolved solids (TDS) in the water; turbidity to monitor the total suspended solids (TSS); and ORP if an oxidizing disinfectant (such as chlorine) is used. Temperature is important if the water is being used for a cooling process, and streaming current is a measurement for determining polymer concentration. Further, polymer aids in the settling or precipitation of the suspended solids.

The controller would be responsible for monitoring the system parameters and turning pumps on and off according to the desired operation. The system may be designed to continuously recirculate from the clean tank until a specific water quality is achieved and thereafter on an occasional basis (e.g., for 30 minutes every four hours). If the water quality is not satisfactory, the controller can prevent the water from being sent to the process.

Communication is always an added benefit for the control system so that alarm conditions can be quickly and effectively communicated and diagnostic information obtained remotely when an issue occurs. Common communication methods include HTML web-based communication over cellular, as well as secure, encrypted point-to-point communication over Ethernet or Wi-Fi. The datalogs generated by the controller can be useful for analyzing system performance and documenting water and sewer savings generated by the system.

The ROI for a stormwater harvesting system varies with project size and scope, geographic location and water and sewer rates. A typical installation for a basic system that collects from 100,000 ft2 of space with an annual rainfall of 40 inches can pay for itself in less than two years. (Based on water rates of $3.35/1,000 gallons, annual collection of 2.4 MG, and a system cost of $15,000 with annual savings of $8,000.)

Summary

Rainwater harvesting is rapidly becoming a standard process for many homeowners, institutions and industrial plants as a way to collect a natural resource and use it to reduce the amount and cost of purchased treated water. As more builders move toward green building, rainwater harvesting will become standard operating procedure. There are many options available for the system based on the desired use for the water, and many experienced system providers can provide a turnkey system that will pay for itself in a relatively short period of time.

About the Author: Lori McPherson has been a Regional Sales Manager with Walchem for 15 years. She has a B.S. in Chemical Engineering from Purdue University and a M.S. in Systems Engineering from Virginia Tech. Prior to Walchem, she held positions as a Process Engineer, Waste Treatment Engineer and Analytical Product Manager specializing in conductivity, pH and ORP measurements. She has published several papers throughout the years, many focused on ORP measurement and control and accurate conductivity measurements.