Construction managers and engineers are increasingly under pressure to bolster efficiencies across their sites and they can make huge gains by using the right equipment for the job. One such piece of equipment is submersible dewatering pumps, which are vital in construction, mining and quarrying applications enabling users to remove water, sludge, and slurry. This article outlines the main considerations for specifying reliable submersible pumps.

What Liquid Needs Pumping?

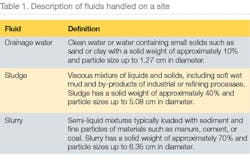

The first consideration is the nature of the liquid being pumped as this has a major impact on the type of pump you will need. Important factors to consider include general composition, the concentration and size of suspended particles as well as the liquid’s pH level, temperature, and chemical content. For example, is it water with fine particles or a much thicker fluid, and how aggressive a media is it? Different types of liquid can be seen in Table 1.

Liquid with a higher concentration of solids is best handled by slurry pumps which are specially designed for handling corrosive and abrasive media. If the liquid is particularly aggressive, then ensure the pump is robust and designed with protection features such as hardened, clog-free impellers, and wear-resistant materials. However, if the fluid to handle contains solids below 50 mm, a sludge pump will be better suited for the job.

What Are the Capacity Requirements?

One of the most important performance considerations is the flow requirement, i.e., how much liquid needs to be moved and how quickly? For example, a pump with a maximum flow rate of 138m3/h will remove water from a pool that is 36 m3 in 15 minutes. However, a pump with a flow rate of 350 m3/h would empty the pool in just six minutes.

For the best value and efficiencies, the pump selected should be able to handle the flow requirements with enough capacity to cope with fluctuations in water level as well as versatility to manage the demands of different sites. A pump which is over-specified and can handle a much higher flow capacity will be unnecessarily expensive and will not provide the most cost-effective solution. On the other hand, a pump that has been under-specified will struggle to transport the media and wear out more quickly, resulting in a shorter life span.

What is the Distance and the Elevation That the Fluid Needs to Be Pumped?

Over what height does the fluid need to be pumped and how far does it need to travel? This will have an impact on the pressure that the pump needs to deliver to ensure it can pump efficiently and reliably. The greater the distance the water needs to be pumped, the more friction is created, which results in pressure loss from the pump. Pumps need to overcome gravity resistance as well as friction losses.

If the suction lift required for dewatering with a surface pump is more than approximately seven meters, a submersible pump should be considered instead. Designed to be totally submerged, it uses the proximity and pressure of the surrounding water to aid fluid movement through the hose and therefore less energy is needed to move the water.

When specifying, check the manufacturer’s published pump curve, which shows head height against flow rate, to ensure it covers the required duty point.

What is Your Energy Source?

If mains electricity is available, an electric pump will be the best and most efficient choice in most cases. Electric submersible pumps are the simplest, most energy-efficient and most economical approach, providing high power in light and compact packages.

If the site is remote and prone to a fluctuating mains supply consider a pump whose motor and starter are equipped with inbuilt electrical protection against varying voltage, phase failure and human error.

Conclusion

Careful consideration of the liquid being pumped, together with the physical demands of the application such as flow, elevation and distance the fluid travels mean engineers will be able to select the most appropriate pump for the job and achieve maximum performance. Other factors to consider also include the energy economy, durability and servicing expense for each pump offered. WW

About the Author: Hrishikesh Kulkarni is the product marketing manager at Atlas Copco Power and Flow.