The Val-Matic FloodSafe® system will be on display at the AWWA show.

Click here to enlarge imagePost 9/11, water distribution systems were recognized as one of the nation’s most vulnerable infrastructure assets. Once again, air valve outlets were recognized as having the potential to allow the entry of contamination into a potable water system.

Val-Matic Valve and Manufacturing Corporation has developed a new Inflow Prevention assembly designed to counter these concerns. It will display its new FloodSafe® Inflow Preventer at the AWWA’s Annual Conference and Exhibition.

Why Inflow Prevention is Important

Air valves play an important role in the operation of distribution systems. Air release valves provide efficiency by preventing air pockets from developing at system highpoints, reducing capacity and increasing pressure loss. Air/Vacuum valves allow the system to discharge large volumes of air upon system start up and admit air when necessary to prevent a vacuum from forming and creating a pressure surge. Reservoir vents also play an important role in the intake and exhaust of air from reservoirs as the water level inside rises and falls.

Venting the outlet of an air valve helps, but “J” pipes still don’t solve the problem of area flooding or the intentional introduction of a contaminate finding its way to the outlet of an air valve or reservoir vent.

Cross contamination and security have brought about many new approaches to protecting drinking water. One of these is the concept of inflow prevention. Inflow prevention is defined as preventing contaminated water from entering a potable water pipeline or reservoir through an air valve or reservoir vent. Inflow prevention is very similar to backflow prevention in that it impedes contaminated water from compromising drinking water. However, most backflow prevention is conceived of as an inline device that reacts to pipeline pressure changes. The inflow prevention concept is conceived of as a way to stop contaminated water from reaching an air valve or vent outlet while allowing the valve or vent to perform its function.

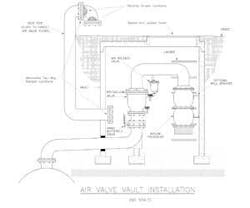

Inflow prevention is important because air valves and reservoir vents are vulnerable to cross connection as well as malicious tampering. There are two types of air valve vault installations, un-piped and piped above grade with a “J” pipe. Left un-piped, an air valve outlet is exposed to atmosphere. If the vault floods and the air valve opens, contaminated floodwater will be drawn into the system. If piped above grade, the same will happen if the floodwater reaches the elevation of the top of the “J” pipe.

Worse can happen through malicious tampering. It is a simple matter to cut off the top of a “J” pipe or drill a hole into it with a portable drill. Once done a corrosive liquid can be poured down the J pipe destroying the valve and leading to flooding and contamination. Worse, a bio-toxin such as ricin or botulinum could be poured down the pipe with very serious public health consequences. Inflow Preventers can substantially reduce these threats.

New System

The FloodSafe® Inflow Preventer is designed to protect vaults from contaminants by preventing the inflow of contaminated water. The FloodSafe assembly is piped to the outlet of an air release valve, air/vacuum valve or vent. As water in a vault rises, the float check in the lower chamber of the device rises, preventing contaminated water from continuing past the chamber.

A redundant upper chamber provides backup in much the same way a backflow preventer works. If contaminated water continues past the seat of the lower chamber the float check in the upper chamber rises, preventing fluid from reaching the air valve outlet. Under normal operating conditions the device provides full venting capacity of the air valve or vent.

The FloodSafe® and other VaultSafe® products including the new FrostSafe® will be on display in the Val-Matic booth at the 2006 ACE show in San Antonio. Visit www.valmatic.com for more information.