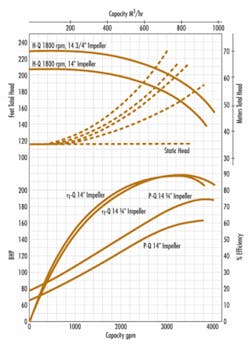

Figure 1: Constant Speed Pump Performance At Two Impeller Trims and Different System H-Q Curves

The key factors that impact pump efficiency are:

1. Operation over a pump's range of flow rates, as a function the pump best efficiency flow rate. The system Head-Capacity curve dictates where a pump will operate on its H-Q curve (the pump will always operate at the intersection between the pump and system H-Q curves), and how far it will operate away from its best efficiency flow rate. The best way to insure that a pump will operate close to its bep (once the system H-Q curve has been established) is to:

a. Select a pump, impeller trim, and/or speed that will closely match the system H-Q curve, near the pump bep (see figure 1). You must determine the actual power and efficiency impact for the possible impeller trims and control means for various pump sizes, to find the best match.

b. For a varying system H-Q curve, consider a Variable Speed Drive (May 2008 Column), with or without hybrid/bypass control (Aug 2008 Column), to keep the pump operating close to its bep.

c. For systems with large changes in flow and/or head, consider multiple pumps, operating in parallel (Nov 2008 Column), or separately. It may be more efficient to include a smaller pump for every day operation, and a separate larger pump for the few times when much higher heads and/or flow rates are required.

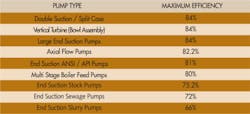

• When considering multiple pumps for parallel operation, it must be realized that, since the bep efficiency of the individual pumps will be impacted by their flow rates, by reducing the flow rate of the individual pumps, you are reducing their maximum obtainable efficiency, as shown in figures 2. So it becomes a trade-off between keeping the flow rate of the individual pumps high, versus staying close to the pump bep, for maximum efficiency.

d. Another efficiency factor to consider when selecting a pump is the operating speed and how it impacts the pump "Specific Speed" (see September 2009 column). As shown in figure 3, maximum obtainable pump bep efficiency occurs in the specific speed range of 2,000 to 3,500, with higher speeds (and flow rates) increasing specific speed, and higher heads lowering the value. So, if higher or lower speed selections (say 1,180 RPM vs. 1780 RPM), higher or lower flow rates, and/or higher heads move the pump closer to or further away from this optimum specific speed range, there will be an impact on the pump bep efficiency.