Pump Maintenance Know-How Tips for Identifying, Correcting Pumping System Problems

It’s no secret that a pump that runs at peak efficiency uses less fuel, experiences less downtime and costs less to operate. The time you spend maintaining your pump is actually an investment in its lifetime performance and value. In fact, there are many ways that a diligently maintained pump can reduce costs, while increasing efficiency.

The following are tips to identify pump system problems and how to correct them:

Commons Signs of Inefficiency in a Self-Priming, Centrifugal Pump

A noticeable difference in pump flow.

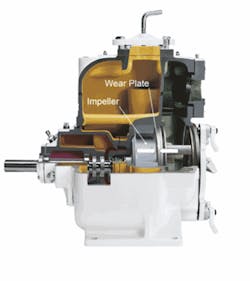

Take notice of the discharge flow. Has it visibly decreased? Is it taking your pump longer to do the same job than it used to? The slowed flow may be caused by a collapsed suction hose lining, a leaking gasket, a plugged suction line or a damaged or worn impeller or wear plate.

To determine the cause of any decrease in flow, the discharge pressure and the suction vacuum should be measured while the pump is operating. If the pump discharge pressure and suction vacuum were measured at start up, the latest readings should be compared to the originally recorded readings. When troubleshooting any pump and system, follow the high abnormal reading. A higher than normal discharge pressure reading will indicate a decrease in suction vacuum, and could be a sign of a clogged or partially clogged discharge line, a closed valve, air unable to evacuate or any obstruction outboard of the point the gauge was installed into the discharge line. It is common practice to install gauges approximately two to four pipe diameters from the pump.

Both gauges can also decrease. If they do, the problem is located between the gauges. In this case, the problem is within the pump. A clog at the eye of the impeller, wear, wide clearances and air induced into the suction line could all cause both gauge readings to decrease. Note that gauge readings almost always teeter back and forth. But again, follow the problem to the highest abnormal gauge reading.

The pump isn’t re-priming as rapidly as it once did.

Most commonly, slower re-prime can be attributed to excessive face clearance. If this is not the cause of your slowdown, check the following:

Check the impeller clearance against the pump manual specifications and adjust if necessary.