Severe drought driving Australia towards seawater desalination for NSW coast

A feasibility study of a 7,000-megaliter/day desalination plant led two city councils on the New South Wales coast to consider desalination as a last resort solution to water shortages.

Desalination within Australia is not widely practiced, but a persistent, long-term drought is driving government authorities to investigate alternative water sources in order to alleviate the demand on existing supplies.

The majority of Australia’s water supply is extracted from surface water rivers, lakes, and reservoirs with the exception of Western Australia and predominately Perth. Seawater desalination is likely to become a possible solution in the New South Wales Central Coast region.

This region is currently experiencing its most severe drought on record and requires the rapid development of potential mitigation solutions to prevent compromising water supplies for residents and businesses alike. As part of the mitigation strategy, Gosford and Wyong Councils’ Water Authority began investigating the feasibility of a seawater desalination scheme as one of its drought contingency measures. Other contingency measures being investigated include groundwater sourcing, effluent recycling, demand management, and a connection into the Hunter Water Corporation water supply system.

The global consultancy MWH were engaged to review and develop the most appropriate concept design for a new seawater reverse osmosis plant to produce 7,000 mega liters a/year of drinking water; to supplement drinking water supply and improve supply security. The purpose of the design was to enable a rapid implementation of a design, operate, and construct contract in the event of continuing drought conditions. The philosophy was that the desalination plant could be operated until such time as the current drought breaks and storage capacities return to normal.

Careful consideration of a number of factors is required during the assessment of the feasibility of a desalination plant, especially one of the sizes suitable to meet the drought relief measures for Gosford and Wyong Councils. It is not only necessary to look at the treatment processes needed to convert salt-laden sea water to drinking water, but also examine the problems of transferring seawater from source to supply and the economic disposal of the left-over salt and other pollutants present in the source water.

First, the source of seawater must be chosen. In this case, many choices for the best type and location for the point where seawater could be sourced were available. Three types of intake were available for assessment.

A near-shore ocean intake at Cabbage Tree Harbour was rejected due to possible problems with kelp and weed ingress in the relatively shallow water depth (up to 3m) as well as amenity and visual impacts from shore-based infrastructure.

An offshore deepwater ocean intake (10m water depth), approximately 500m off Jenny Dixon Beach was rejected due to relatively high cost, maintenance issues with marine growths, and possible impacts with shipwrecks.

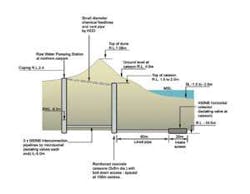

The third option was adopted. Beach wells draw water from the ocean from under Lakes Beach. A horizontal beach well arrangement extending under the beach into the tidal zone can access the seawater needs of the desalination plant without impact on nearby groundwater-dependent ecological communities. The seawater would be filtered through the beach sands providing high quality source water.

The reasons for selection were not based solely on the technical assessment. Given the natural beauty associated with each of the locations, the visual impact and loss of recreation areas for the public were strong drivers in the selection of the Beach Wells. Other factors that had to be considered included access for maintenance, the likelihood of impact of marine life, and the effect on recreation waters and downstream treatment process. The ability to construct the intake system was also a key factor in selection.

Second - disposal of concentrated brine reject. The efficiency of seawater desalination using reverse osmosis (RO) membrane technology is still limited to about 50 percent; i.e. twice as much water must be transferred, pre-treated, and then pumped to high pressures for passing through the reverse osmosis membranes as is produced as final product. Half of the pre-treated water is rejected as a concentrated stream, commonly referred to as the brine reject. This concentrated stream represents quite probably the single biggest headache in desalination. The most accepted method for disposal is to return it back to the ocean via a suitable pipeline. This pipeline represents a significant cost to a desalination project depending upon the location of the treatment plant, and consideration must be given to the impact at the point of discharge on the marine environment. This can lead to long sea outfalls with high velocity nozzles to ensure adequate dispersion and dilution to minimize the effects of concentration.

In this case Gosford and Wyong councils also operate the local wastewater treatment plants, with interconnections of each of the discharges leading to a single discharge point located at the Toukley wastewater works. After careful review, it was decided that it would be beneficial to co-locate the new desalination plant at the Toukley facility, with appropriate segregation of the drinking and wastewater facilities in order to use the existing long sea outfall for the wastewater for the brine disposal. The quantity of brine reject and the daily wastewater flow was approximately equal, given rise to a mixed salt concentration equivalent or close to that of the surrounding seawater, thus reducing the impact on marine life at the point of discharge. The only downside of mixing to achieve a seawater salt concentration is the potential for marine life to grow on the inside of the pipeline, where previously they had been discouraged by the low salt concentration, and potentially reducing the capacity of the pipeline.

By co-locating the desalination plant, other plant residuals such as sand and pre-treatment backwash waters could also be disposed of (with appropriate pre-treatment) through the wastewater outfall or with the residuals from the wastewater treatment plant.

Third - reduce high energy costs and consumption of desalination. As mentioned earlier, given the poor recovery (efficiency of 50%) of the RO process and the need to pressurize the feed water to levels above 80 barg (800m water head), the associated power costs are considerable. A typical value of 7 kwh per cubic meter of water treated would be expected in terms of power consumption if no energy recovery were practiced. To reduce power consumption, a number of methods are available that take advantage of the high pressure remaining in the brine reject stream (which is almost at the feed pressure as little loss occurs with the RO vessels on the reject side). These methods include the traditionally used Pelton Wheel or Turbo charger and the more recently available work exchangers. Of these, the work exchangers offered the greatest efficiency and were selected as part of the plant design for this project. The pressure energy remaining in the reject stream is transferred via a series of reciprocating pistons to a proportion of the feed water, thus reducing the size of the inlet feed pumps by as much as 50 percent and requiring only a small pressure booster pump on the remaining flow. Using this technology made a considerable decrease in the specific power consumption, reducing it down to 4.0 - 4.5 kwh per cubic meter of treated water.

Lakes Beach Seawater Intake Section

The energy costs associated with desalination are still considerably higher than those for treatment of conventional water sources, with typical power requirements of less than 0.5 kwh per cubic meter, although highly dependant of the raw water quality.

Another consideration associated with desalination is the need to remineralize the water post treatment to reduce the aggressive effects on concrete structures and to make it more palatable to the consumer. In the case of Wyong and Gosford, the existing drinking water quality had to be matched as closely as possible to minimize the customer impact.

In terms of costs, the overall out-turn cost for the supplying an additional 7,000 mega liters per year of desalinated water were estimated at more than 75 million Australian dollars. The operating costs associated with the plant must take into consideration the cost of regular RO membrane replacement, increased numbers and required skill level of operators needed, and the cost of transferring, treating and then disposing of 100 percent of more water than produced.

Final decision

The Wyong and Gosford councils’ review led to the decision that desalination would be the last resort for the Central Coast. However, the design of the desalination plant would be developed to a point where it could be implemented quickly if the drought continued and other contingency measures failed. Given the high capital and long-term operating costs with the associated sustainability issues, seawater desalination can be considered to be last resort in solving the long-term drought problems faced by Australia’s Central Coast.

Authors’ note

Ajay K. Nair is the principal process engineer for MWH UK and Bernard Clancy is the project manager for MWH Australia Pty. For further information please contact [email protected].