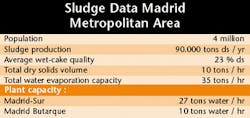

Once completed, two thermal drying facilities in Madrid will serve a population of four million. Photo by: Vandenbroek International

Click here to enlarge imageOverall sludge production in the Madrid area amounts to approximately 90,000 tons of dry solids a year, which requires a total treatment capacity at the Madrid-Sur and Madrid-Butarque sites of about 11 tons/hr as dry solids, given 35 tons of water evaporation per hour.

The sludge types at Sur and Butarque are characterised by two-stage anaerobic digestion of primary and secondary sludge. Upstream of the digestion process, sludge is pre-treated with the use of rotary screens and dissolved-air-flotation. After secondary digestion, belt presses and centrifuges mechanically dewater the sludge. The wet cake has an average dry solid content of 23%.

The treatment concepts of the Sur and Butarque treatment facilities are similar. Sludge cake from small regional wastewater treatment plants is transported to the imported cake reception facilities and pumped into intermediate silos. The cake is then conveyed to two-line sludge dryers.

Both plants generate electrical power with natural gas-fuelled gas turbines (Sur) and gas engines ( Butarque). The generator-exhaust gas is the main heat supply for the drying process, covering approximately 100% of the total dryers' heat demand.

The rotating drum dryers are of the indirect convective type; the hot exhaust gases of the gas turbines (Sur) or gas engines (Butarque) transfer heat via heat exchangers to the recycled dryer gas. The dryer gas loop is nearly closed. About 10% of the gas volume passing through the drum must be taken out of the system for final treatment, which involves dedusting and chemical scrubbing.

The final product is granulated sludge, classified into two to six millimetres with a dry-solids concentration of more than 90%. Before final storage the sludge granules are cooled down to below 50°C to prevent self- heating during storage time.

The design of sludge drying plants at wastewater treatment plants in Valladolid and Leon with capacities of two to three tons of water evaporation per hour are similar. The Valladolid dryer, in operation since November 1999, operates continuously within the guaranteed performance criteria, i.e. granule size, moisture content, fuel consumption and reliability.

Author's note

Mark Kragting is the account manager for Grontmij Vandenbroek International bv, located in Driebergen, Netherlands.