The newly emerging application of wastewater reuse is hyped to become the most promising process for membranes in the water industry. Dr Graeme Pearce discusses the challenges involved with membrane filtration as a pre-treatment to reverse osmosis, using the case study of Orange County, California.

Membranes have been used in water and wastewater applications since the 1960's. However, initially membrane processes were felt to be too expensive for this field, and were only applied in niche applications or special circumstances. This changed during the 1990's due to the emergence of several drivers, including legislation to achieve improved treatment standards, and resource scarcity, which created the need to use membranes on saline or wastewater sources. The rapid uptake of membranes since 2000 has led to a dramatic fall in costs, to the extent that membranes now often compete with conventional processes, while achieving much better quality standards.

There are two classes of membrane process used in the water and wastewater field. The first category includes reverse osmosis (RO) and nanofiltration (NF). These membranes have a dense non porous separating layer cast onto a porous support, and are used for the removal of dissolved substances. The second category is membrane filtration, in which a micro-porous separating layer provides a barrier to the finest particles present in the feed source but allows dissolved components to pass through. Membrane filtration is often used as a treatment process in its own right, but may also be used as pre-treatment to an RO stage.

An early application was in the use of RO and membrane filtration for industrial water treatment, either for general process water use or for ultrapure water production. This has now been surpassed in importance by the use of membrane filtration in drinking water treatment to remove turbidity and provide a disinfection barrier, particularly to parasitic microorganisms such as cryptosporidium and giardia.

One of the longest established uses for membranes in water treatment is in the use of RO for desalinating seawater. Even in the Middle East where energy is cheap, RO has recently taken over from distillation processes as the preferred technology for most duties. A recent new application of membranes in desalination is in the use of membrane filtration as a pre-treatment to RO, and this area has grown at a dramatic rate since 2005.

Last but not least, membranes are now being used in the newly emerging application of wastewater reuse, the fastest growing and potentially most promising membrane application in the water industry. In fact, membranes have been an enabling technology for this application, since without membranes, wastewater treatment to a standard guaranteeing quality and security would be too difficult and costly.

RO is required to ensure that dissolved organics, and sometimes salts, are removed to a sufficient extent. Membrane filtration is needed as a pre-treatment to the RO, and this application will form the subject this paper. Without membrane pre-treatment, stable operation of the RO has been found to be unachievable, so the advent of the membrane filtration boom for drinking water in the late 1990's enabled the commercial realization of this application.

Technology

There are two types of membrane filtration technology for water and wastewater treatment, namely ultrafiltration (UF) and microfiltration (MF). UF has pores of 0.01 – 0.02 μm, while MF for water treatment has pores of 0.04 – 0.10 μm. In wastewater applications, coarser MF pore sizes of 0.2 and 0.4 μm can be used, but the finer MF membranes for water duties are also suitable. The separation spectrum illustrated in Figure 1 shows the particle size that the different filtration technologies are designed to address, with some examples of common challenges.

The figure shows that membrane filtration is two to three orders of magnitude coarser than RO. MF removes common particles found in water including bacteria and other microbial organisms, while UF removes viruses in addition, thereby providing a physical disinfection barrier. For RO pre-treatment of wastewater, membrane filtration is normally used in combination with coagulation to control fouling, ensure operational stability and improve removals of dissolved organics.

Resources

Water resources are under pressure from increasing population, especially in arid regions, and greater use of water per capita due to economic development. Some attempts have been made to reduce water usage through conservation programmes, but so far this has just had the effect of containing growth.

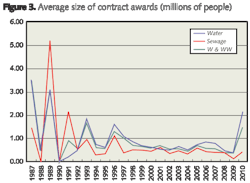

Not only is demand rising, but traditional resources will become less available in the future. Water supply is currently obtained mainly from freshwater resources, as illustrated by Table 1 below [1]. Surface water is the most important water resource, but groundwater is also a significant contributor accounting for 36% of total. New resources such as desalination and wastewater reuse accounted for just 0.5% of the total in 2005. However, the balance of resource supply will undergo a fundamental change in the coming decades. Groundwater is effectively a non-renewable resource. Millennia are required for groundwater resources to accumulate, but these resources can be depleted in just a few years.

Combined with the inexorable reduction of groundwater availability, the quality of groundwater is under threat due to a variety of factors, such as saline intrusion near the coast as the water table declines due to over abstraction. Also groundwaters are becoming contaminated by industrial and agricultural residuals caused by increasing fertiliser and pesticide since the Second World War. The effect of this activity has taken some decades to become established, but since the early 1990's, treatment processes have been required in the developed world for groundwater sources to control contaminant levels.

In the long term, new sources such as desalination and wastewater reuse will have to replace groundwater, and the beginning of this trend has already started to occur. Growth of novel resources significantly above the underlying growth rate of water use is therefore assured for the foreseeable future. On top of this, the growth rates for membrane filtration processes will be even greater, as membranes become established as the dominant technical solution. Thus currently desalination and wastewater reuse markets have annual growth rates of 8% and 14% respectively, but the use of membrane filtration in these applications is growing at 17% or more [1,2].

Currently, 10% of water abstracted is collected as wastewater, and just under half of this is treated prior to disposal [1]. However, only a small fraction of treatment is to a reuse standard. Wastewater is therefore available as an abundant resource for treatment to a reuse standard. Most reuse at the moment is destined for industry and agriculture, with just 11% for municipal use. However, municipal applications are undergoing dramatic growth, which will be illustrated by the case study at the end of the paper.

Energy Use

Unfortunately, these novel water sources require much more energy for treatment than traditional freshwater resources, and this will become a major consideration for the future. In particular, desalination is very energy intensive, and this provides an important motivation for developing wastewater reuse as the default option where resource constraints occur, leaving desalination for situations where there is no other choice. Energy efficiency in water supply is now recognised as a major driver for the selection of alternative resources.

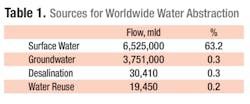

Figure 2 shows the energy cost of treating a variety of different water sources, and compares these treatment costs with the cost of transport and distribution [3]. The arrow at the top of the figure represents the spectrum of the energy costs for treatment. Freshwater energy costs are very low, typically 0.2 – 0.3 kWhr/m3, with desalination costs at least an order of magnitude greater. Brackish water and wastewater reuse lie in the middle of this spectrum, typically at about 0.8 – 1.0 kWhr/m3. If nanofiltration is used for emerging contaminants, it will use energy just below this level, whereas novel wastewater treatment processes such as membrane bio-reactors have energy levels somewhat above the brackish water range.

Saline sources are energy intensive, since significant power is required to overcome the osmotic pressure in treatment. Estuary sources, such as the Thames Water project at Beckton in the East End of London, provide a lower energy cost option. However, RO in wastewater reuse operates at lower pressures, since the osmotic pressure is low, and these sources are normally the best sustainable option for new resource development.

The figure illustrates that the decision on resource development is made more complicated when considering distribution and transport costs. The pumping energy of transferring water is significant. For example, in the highly populated London area, the average cost of distribution is 0.6 kWhr/m3 [4] so the proximity of the resource to the point of use could be a significant. Transport costs are much more extreme in arid areas such as California, where the State Water Project, which transfers water from the north of the State to the densely populated south, uses as much energy as a local desalination plant [5]. Desalination can therefore be justified in energy terms compared to long distance transfers in such cases, but wastewater reuse is likely to be the first option that should be considered.

An attraction of wastewater reuse is the flexibility of the resource. Wastewater is already collected, especially near urban centres. In addition, it is normally treated for disposal, and the energy cost of the conventional activated sludge process used for this purpose typically uses about half of the total energy cost of reuse.

The marginal energy cost of taking wastewater already treated for disposal is not that great, perhaps around 0.5 kWhr/m3, which makes the additional energy cost of this resource much closer to a surface water resource. Also, the resource is flexible, since the treatment plant can be easily designed to provide a variable output capacity.

Case Study: Orange County, California, USA

Wastewater reuse projects have been implemented at large scale in several areas of the world during the first decade of the 21st century. The highest profile plants are those in Singapore, where six large reuse plants have now been installed. The most recent large scale projects are those in Queensland, Australia, and Qatar and Kuwait in the Middle East. The case study featured in this paper will review the plant in Orange County California [6].

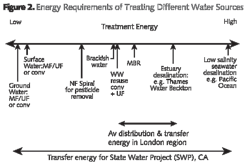

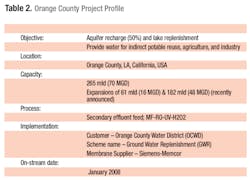

The Orange County Water District (OCWD) has been considering wastewater reuse schemes since the early 1970's, and has run long term demonstration scale plants based on RO preceded by conventional pre-treatment. The conclusion of these early studies was that reuse was not commercially viable. The advent of membrane pre-treatment inspired a revisiting of this conclusion, and the consequence of the re-assessment was the implementation of the scheme, as set out in Table 2.

The recovered water will be used to recharge the coastal aquifer, and will augment subsequent abstraction for industry, agriculture, and indirect municipal reuse. The plant uses submerged polypropylene (PP) MF membranes from Siemens-Memcor. Feed temperature ranges from 21-27oc and the membrane plant operates with an actual average gross flux of 31 lmh and a recovery of 93%. A chlorine residual of 1-4 ppm is dosed continuously, converted to chloramines due to the ammonia residual, making it compatible with both MF and RO membranes. The Clean In Place interval is 20-60 days. A photo of partly filled membrane racks used at the plant is shown in Figure 3.

The plant has operated well since start up, and is already being expanded, with a future expansion planned. Stable RO performance has been achieved. The PP membranes have also been used on several of the plants in Singapore, though polyvinylidene difluoride (PVDF) membranes have been used on a similar reuse application in Australia.

Conclusions

References• Wastewater treated by conventional activated sludge provides a suitable feed for membrane treatment

• The wastewater reuse market is growing rapidly, and provides an opportunity with excellent business potential for membrane filtration

• For wastewater reuse, UF/MF membrane pre-treatment is essential for low cost RO

• The energy cost and Total Water Cost for wastewater reuse is significantly below that of seawater desalination

• MBR – RO has higher energy costs than conventional wastewater treatment followed by UF/MF – RO

• Membrane filtration case studies in wastewater reuse have provided good experience for the water Industry.

[1] Global Water Intelligence Wastewater Reuse Report, 2005

[2] Global Water Market 2008: Opportunities in Scarcity and Environmental Regulation Global Water Intelligence, October 2007

[3] UF/MF pre-treatment to RO in seawater and wastewater reuse applications: a comparison of energy costs G K Pearce, Desalination 222 (2008) 66–73

[4]Closing Submissions; Appeal Reference: APP/G5750/ A/05/1184751 Mayor of London's Office (www.london.gov.uk/mayor/planning)

[5] Import or Desalinate Water Desalination Report, p2-3, 25th June 2007

[6] Guidebook to Membrane Technology for Wastewater Reclamation Ed M Wilf, Balaban Desalination Publications, C

Author's note: Dr Graeme K Pearce is a membrane technology specialist with 25 years experience in the membrane industry and is principal at Membrane Consultancy Associates - a consultancy practice providing expert advice and guidance in membrane technology for liquid separations, founded in Sept 2005. For more information please email: [email protected].

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles