By Rob Adams

Federal Stormwater Phase II regulations were enacted to protect waterways from being polluted by runoff from impervious surfaces, such as building roofs and vehicle parking lots, during a storm event and also to address the recharging of groundwater aquifers. These regulations are the driving force behind the increasing number of stormwater basins being constructed for retention, detention, and infiltration of stormwater runoff.

Applications

Stormwater management plans are required wherever any new impervious surfaces are constructed. Stormwater containment technology can be applied to new construction and reconstruction in several ways, but the first decision to be made is whether the runoff will be directed into an aboveground system or some form of underground system.

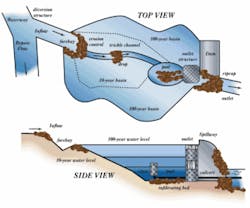

If an aboveground system is chosen, a wet/dry pond or grassy swale needs to be located some distance from the newly constructed building and/or impervious parking surfaces. Typically, this basin would be installed on a large portion of property slightly downhill from all runoff surfaces. All runoff from the new construction would be directed into the pond where it would fill the pond and would either be allowed to soak into the soil below (infiltration) or be piped through a weir system to a nearby receiving body of water at a lower flow rate than the inflow (detention).

If the decision is to use an underground system, there are several products/systems, each with its own unique advantages and disadvantages, from which to choose.

StormTank installation used for structural load testing.

The conventional method of subsurface stormwater storage has been to direct runoff to stone-filled excavations (French drains) where the collected rainwater infiltrates into the ground below the basin. As the need for stormwater containment has increased, innovative ways have been developed to manage runoff in more effective, space-utilizing ways. Various kinds of concrete vaults, pipe chambers, and plastic structures have come to market. These new systems can be designed for use under parking lots, roadways, athletic fields, and other hard or grassy areas. When properly installed, these structures will allow volumes of runoff to be contained underground, out of sight, to be discharged, reused, or infiltrated into the native soil to recharge local aquifers.

System Design Considerations

Detention or infiltration?

A detention-type system holds stormwater runoff before allowing it to be discharged as controlled outflow. An infiltration-type system allows all the flow into the system to infiltrate into the ground below and, ultimately, into nearby aquifers. Several factors must be considered when deciding which system to use.

Types of Soils

The soils in a potential site should be evaluated before deciding between a detention or infiltration system. Sandy soils allow unimpeded infiltration of collected stormwater into the ground below the system, while a clay base could act as a liner and allow little water to soak into the ground below.

Location of the Stormwater System

If the system is to be located near a stream, river, pond, lake, or other body of water, a detention system might be the better choice. Stormwater flow collected and contained during rain events can be directed to the receiving body, at a lower flow rate, through a control valve located in the outflow piping. If the receiving body is some distance away, the cost of piping alone could make an infiltration system more desirable, as long as the soil is suitable for this purpose.

Calculating Stormwater Storage

For a new stormwater storage system, the impact of all the surrounding impervious surfaces (e.g., roofing, parking, and road surfaces) during a storm event must be taken into account. This surface area is referred to as the Total Area of Influence. To calculate the total volume of stormwater capacity needed to adequately contain rainfall runoff from these surfaces, multiply the Total Area of Influence by the average rainfall data from 2-year, 10-year, 50-year, and 100-year flood events from that specific location. Stormwater containment equipment suppliers can assist in these calculations, but the design engineer is ultimately responsible for determining what minimum storage volume is required per local enforcement codes.

Choosing a Location

The depth of a stormwater system installation is determined by such factors as movable rock layers, distance from surface to water table, existing infrastructure, and soil quality. Different soil types may exist in a single property and, depending on whether the system will be used for infiltration or detention, the system should be located where the most compatible soil type is found.

Aboveground stormwater systems are usually located away from building entrances and main parking areas to avoid interference during construction and for other land-use and aesthetic reasons.

Underground stormwater systems, hidden from sight, can be installed under parking lots or in front of main entrances without any aboveground interference.

Other Design Considerations

There are currently many different types of stormwater containment systems and each has its advantages and disadvantages.

Void Space

The void spaces of underground systems currently available range from as low as 40% for conventional crushed rock systems to as high as 97% for more technologically advanced solutions, like Brentwood StormTank modules, that use strong, low-volume support systems. Of course, in an aboveground pond, 100% of the volume is usable.

Residential installation of plastic modules for onsite infiltration.

Strength

Underground systems must be able to handle heavy vehicle loads without failure. Most systems test to, or claim, H-20 loading capability. Concrete vaults, pipe chambers, plastic structures, and stone fill are all being used in H-20 capable underground stormwater containment systems. Load ratings of H-25 are available in some systems to provide longevity of products in the field.

Footprint

The available surface area of a site may be a determining factor in the selection of a particular type of stormwater containment system. With aboveground ponds, all the surface area is “lost” to other uses. Underground systems, such as arched chambers, require a large footprint to achieve the necessary storage volume, as chambers cannot be stacked on top of one another. Where surface area is limited, concrete vaults and plastic structures are a viable choice for achieving the necessary storage volume with a smaller footprint. Plastic structures, usually in modular form, can be stacked to a required depth.

Cost

Aboveground holding ponds require consideration of the actual cost and the “opportunity cost” of the land, the excavation, and the landscaping/beautification of the pond and surrounding property. Silt removal and land maintenance are additional costs to be considered. Where land is available, this is the lowest-cost alternative.

In a concrete vault system, the costs of excavation, heavy equipment usage, labor, backfilling, and dressing/finishing need to be considered, of course. But the material cost of the vault structures makes this the highest-cost system.

The costs of a French drain system would include excavation, stone and other materials, and backfilling the installation to a finish grade. Since these systems can easily clog or foul, the cost of maintenance or a subsequent reinstallation would have to be considered. Because the void space in this type of system is 25 to 40%, it would be a high-land-use, low-cost alternative.

Arch chambers and plastic structures include costs for the materials, excavation, final backfilling, and final site work. These types of systems also require labor to assemble and install the products, but there are no special equipment or tool costs, since they are typically lightweight and can be installed by hand.

Adaptability to Site

Aboveground systems must be located in areas where storm runoff can easily flow into the system, but away from buildings, paved areas, or other property intended for public use. Underground systems must be designed around existing infrastructure, new development, or unacceptable soil conditions. Understanding the features of a stormwater containment system can be helpful in determining how a system can be adapted to different development sites.

Pretreatment

Silt, oily substances, and other contaminants can enter most stormwater systems. Some have more built-in safeguards than others, but the best way to protect any system from clogging or fouling is to pretreat the stormwater runoff. Pretreating the runoff can also extend the life of a system.

Maintenance Issues

Aboveground systems may require removal of trash from the basin in addition to regular mowing and weeding.

Soil and other debris can easily plug the void space of a typical rock fill system, reducing its storage capacity and allowing stormwater to overflow and flood the surrounding area.

Various kinds of plastic structures have come to market. These new systems can be designed for use under parking lots, roadways, athletic fields, and other hard or grassy areas.

Concrete vaults and some plastic structures have wide-open interior spaces that can be accessed through a manhole with a vacuum-truck hose for flushing the system and removing settled solids. Other plastic structures and pipe chambers are more difficult to access if flushing is needed. Contact the stormwater containment system supplier regarding the maintenance they require, as well as how to perform those maintenance functions.

Assembly

Some pipe chambers, concrete vaults, and plastic structures require assembly of the basin, often requiring a crane or other piece of machinery to lower the structures into the excavation. Some structures are assembled on site, usually to save space and freight costs. The components are typically hand-assembled and placed in the installation by one or two laborers.

Installation Considerations

Excavation

The excavation must be prepared properly or the equipment used within it may not work as intended. Often all that is needed in an aboveground system is adequate soil removal and the correct grading. When preparing an underground site, allowance for a base, side fill, and top fill must be calculated. A flat, level bottom, using compacted native soil or crushed stone, is needed so that any placed product will fit and assemble properly into a complete, seamless basin.

Materials

Before excavation begins, all materials needed to install the basin should be on the jobsite: crushed rock, geotextile fabric, the stormwater product, topsoil, and asphalt (if installation will be under a parking lot). Native soil will be removed and little will be reused. Geotextile fabric is used to line the stormwater product installed in the excavation. Crushed stone is used to backfill around the perimeter and for top fill before applying either topsoil or asphalt.

About the Author:

Rob Adams is a graduate of Penn State University with a degree in Mechanical Engineering. He has over 5 years experience in the wastewater and water industries and is currently the Stormwater Product Manager for Brentwood Industries in Reading, PA.