Figure 1: Stackable and modular units make up the subsurface stormwater harvesting and detention system. |

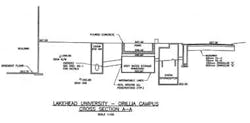

Michael Buske, CET, along with engineer Tim Collingwood, project manager with CC Tatham & Associates, designed the unique system to capture stormwater from the adjacent road. The runoff flows into a catch basin, moves through a filtering system, flows to a chamber for storage, and from there is pumped to the aboveground water feature. The underground chamber was originally designed to be both a harvesting (gray water reuse) and a detention (exfiltration and release) system. The system also includes an outlet pipe to the city’s combined storm sewer system and a manhole for maintenance. In addition to supporting the water feature, some of the captured gray water is also used for toilet and urinal flushing to reduce fresh water use in the building.

According to Buske, during construction, it was determined that the system should be fully wrapped in the impermeable liner since it would be very difficult to interface the permeable top and impermeable bottom liners. This turned the underground portion into a full capture and reuse harvesting system. When the system reaches capacity, it utilizes an overflow pipe connected to the municipal stormwater system.

For the underground harvesting system, engineers selected Rainstore3 by Invisible Structures, Inc. (Golden, CO). Modular and stackable, the system is designed for underground storage of water for retention, detention and harvesting. The entire chamber at Lakehead University is comprised of 6,000 units stacked into two-meter-high cells and is capable of holding 564 cubic meters of water.

“This system was selected for the high storage volume in a smaller area as compared to a clear stone, French drain-type design,” said Collingwood. It was also attractive to the designer for its structural ability to support the load of the water feature pond directly on top of the system.

“We needed to calculate the compressive load of the water, the concrete and the granular aggregate above the Rainstore3 chamber to see the effect it would have on the system,” explained Kate Wright, engineer with Invisible Structures. It was determined that the filled ponds and components would exert a point load of 505 psf on the chamber, well within the limits of the system, which can withstand in excess of H-20 bridge loading standards.