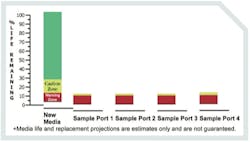

Purafil engineers design systems to handle more than a one-ton chlorine release. Field analysis shows that after the release it still has over 10% life remaining. The media life analysis (MLA) shown above depicts the Purafil Chlorosorb media after the release within the FOC-1 unit located at the Moccasin Bend WWTP, which generates 5,000 cfm.

About the site

The Tennessee River and Cumberland Escarpment intersect to form the historical Moccasin Bend in Chattanooga. The 925-acre area's significant development and relevance for its original Native American inhabitants span more than 10,000 years. In fact, residents and historians, alike, have lobbied to preserve Moccasin Bend for more than 20 years. In turn, the plush grounds nestled within the Chickamauga and Chattanooga National Military parks have also been deemed an Archaeological District among the National Register of Historic Places, a National Historic Landmark and a Native American Burial Ground.

According to The Friends of Moccasin Bend National Park, a nonprofit organization, the area represents the historical Native essence of Chattanooga. Its place in history, which predates the Common Era, has been chronicled with life and its necessity for potable water.

Subsequently, the wastewater treatment plant was built in the 1960s and bears the same name. Moccasin WWTP serves 400,000 people, treats 140 million gallons of water per day (MGD) and has a maximum hydraulic capacity of 220 MGD.

About Purafil ESD

Purafil ESD's EGSs are more advantageous than toxic, liquid wet scrubbers. Purafil introduced an easy Retrofit Plan for Liquid Caustic Scrubbers transform wet scrubbers and protect wastewater facilities and their communities from potential risk.

Purafil ESD is the premier single-source manufacturer of clean air products throughout North America and Europe.

A division of Purafil Inc., Purafil ESD manufactures a broad range of dry-chemical media and scrubbers that remove odors, prevent toxic gas releases, and corrosion of electronics. Visit our Web site at www.purafil.com.

November 2009

###