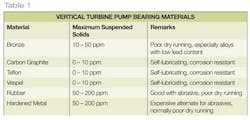

Bearing Material Options

Table 1 lists the classes of column and bowl assembly bearing materials generally available for VTPs, with each manufacturer typically offering their own specific alloys. The bronze alloys typically offered have very low (if any) lead due to environmental concerns, which reduces their dry-running ability. Carbon graphite bearings probably offer one of the most efficient dry-running capabilities but have very low solids/abrasive tolerance; they are also available with a variety of fillers. Teflon bearings also have excellent dry-running capability and poor abrasive tolerance, plus they are available with a variety of fillers. However, Teflon bearings cannot be retained with a press fit due to the potential of cold flow.

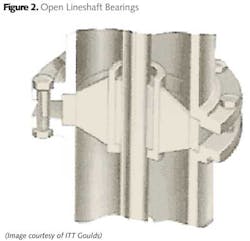

Vespel bearings are also much like Teflon bearings but with improved dimensional stability, and they are also available with a variety of fillers, including Teflon and carbon. Rubber bearings are primarily used for open lineshaft column applications and are very proficient at handling solids, as long as they are not too sharp. However, they have poor lubricity and should be wetted prior to startup, which could pose a problem with deep settings (over about 100 feet), especially if the pump does not have a foot (check) valve and it takes too long for the pumped liquid to reach the upper bearings. Rubber bearings are seldom used for bowl bearings due to the larger required running clearance. Finally, hardened surface metal bearings are also available, such as chromium oxide and tungsten carbide, for abrasive/solid applications, but they are expensive and also have poor lubricity for handling air and/or vapors.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. With offices in Washington, N.J., he can be contacted via email at [email protected].